At a time when we are committed to improving product accuracy and manufacturing efficiency, understanding the latest developments in Taiwan's PVC injection molding market has become an indispensable part of the industry elite. As a new star in plastic molding equipment, micro-injection machines have demonstrated unparalleled advantages in many fields with their highly precise injection molding capabilities.

This article will give you an in-depth understanding of the role of micro-injection machines in Taiwan's PVC injection molding market, from macro market trends to micro technological advances, and analyze its impact on the current manufacturing industry one by one. You will get first-hand market analysis reports and expert opinions to more accurately grasp the pulse of the market, or take the initiative in business decisions.

Key interpretation

- An in-depth analysis of the dynamics of Taiwan's PVC injection molding market will provide you with insights into industry opportunities.

- Reveal the precision molding capabilities of micro-injection machines and detail how they improve product quality.

- Explore innovative trends in plastic molding equipment and learn about future development directions.

- Provide market application cases of precision injection molding technology to make your business more forward-looking.

- Analyze the impact of environmental protection regulations on the injection molding equipment market and guide manufacturing policies that are consistent with green development.

Overview of PVC micro-injection molding device

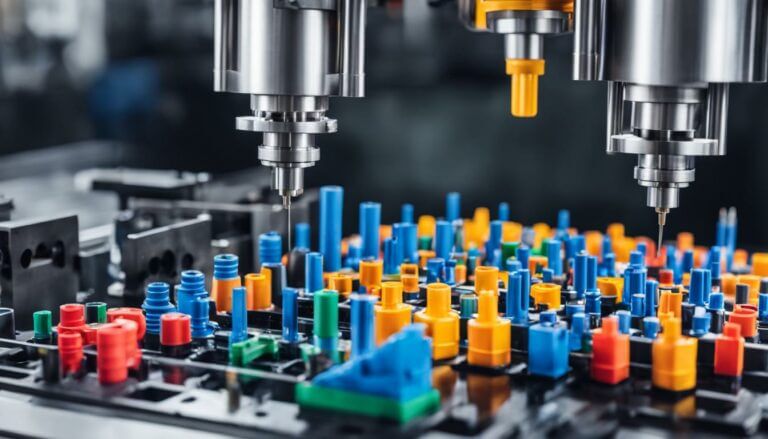

The manufacturing industry is currently experiencing rapid technological evolution, among which,Micro plastic moldingTechnology has gradually become a hot topic in the industry due to its high efficiency and precision. For businesses that need to mass-produce small precision parts,PVC injection machine characteristicsDemonstrated unparalleled advantages.

The core of the PVC micro-injection molding device lies in its high-pressure injection molding system. This system can accurately control the amount of material injected into the mold to achievePrecision plastic molding. This technology provides high-quality and consistent solutions for areas requiring extremely high precision, such as the electronics, medical and automotive industries.

| characteristic | PVC micro injection molding device | Traditional plastic injection molding technology |

|---|---|---|

| Material utilization | Efficient and reduce waste | relatively low |

| Production speed | Fast and suitable for mass production needs | Slower, not suitable for urgent orders |

| Accuracy | Extremely high, suitable for precision components | Normal, may require post-processing |

| Application scope | Widely, especially in precision industrial fields | Generally, suitable for large size parts |

Through comparison, we can clearly see the advantages of PVC micro-injection molding equipment in various aspects, especially inMicro plastic moldingapplication. Not only can it meet the stringent precision requirements of modern manufacturing, but it also shows great potential in increasing production capacity and reducing costs.

Global market trend analysis

Under today's international market trends,Injection molding equipment requirementsis continuing to rise due to the booming global manufacturing industry and increasing consumer demand for high-precision plastic products. To understand how complex this change isIndustry development trendsTo remain competitive, the following will provide important market analysis data and insights.

Different regions around the world have different demands for PVC micro-injection molding equipment, each showing unique market characteristics. We conduct a detailed analysis of regional market performance and key factors affecting the market so that you can gain insight into potential business opportunities in each region.

| area | demand growth rate | Market characteristics | the main factor of influence |

|---|---|---|---|

| Asia-Pacific | Growing rapidly | Rapid development of manufacturing industry | Population increase and economic development |

| North America | Steady growth | Leading by technological innovation | Advanced manufacturing and R&D investment |

| Europe | Moderate growth | Strict environmental regulations | Green transformation and innovation policy |

| South America | initial development | Great market potential | economic structure adjustment |

| Africa | Slow growth | Infrastructure initial stage | Foreign investment and degree of industrialization |

As can be seen from the above data, injection molding equipment has varying degrees of demand in various regions around the world, reflecting a wide range of application fields and industry connections. Understanding these trends will help you keep your finger on the pulse of the market and provide guidance for your business strategy.

Product innovation and technological progress

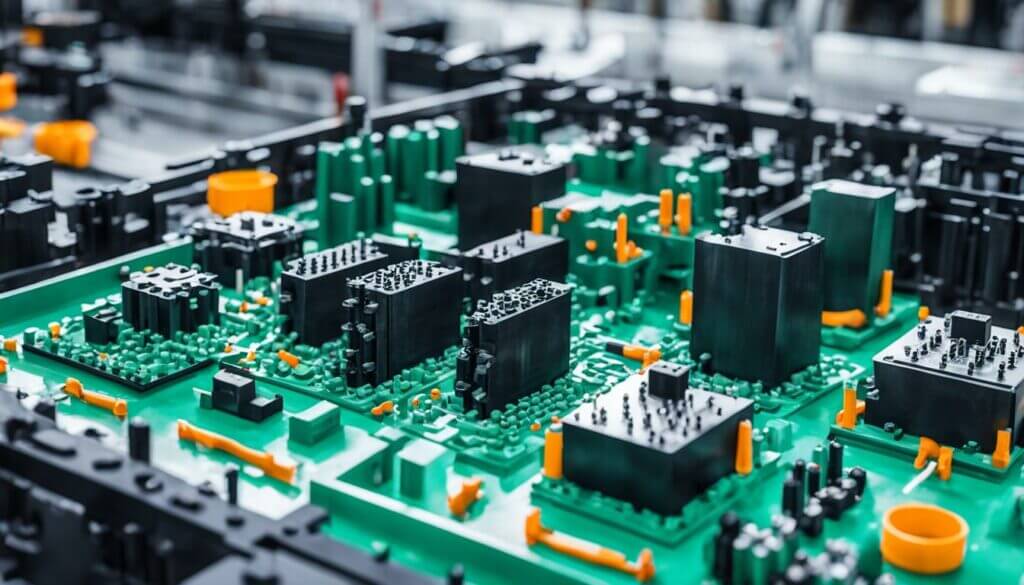

In today's rapidly changing plastics manufacturing industry,Innovative injection molding technologyhas become a key factor in driving the industry forward. For companies seeking to improve their competitiveness, master the latestAutomated molding solutionsandEfficient plastic moldingTechnology has become particularly important. These technologies not only speed up production but also enhance product consistency and quality.

Your business can benefit from this innovation as it involves the injection process from the input of raw materials to the finished product. For example, the use of advanced injection systems can achieve precision control and maximum efficiency in material use, which is especially important for PVC micro-injection molding devices that require high-precision finished products.

existAutomated molding solutionsOn the other hand, modern production facilities have begun to use robotics and artificial intelligence algorithms. These technologies can perform real-time monitoring and adjustment during the production process, thereby ensuring higher operational accuracy and lower scrap rates.

also,Efficient plastic moldingThe application of technologies such as hot runner systems and variable-speed injection processes not only significantly improves production efficiency, but also helps companies reduce energy consumption costs and achieve the goals of green manufacturing and sustainable development.

As these technological innovations continue to develop, your company will be able to better adapt to market changes, meet customer demands for high-quality products, and gain a leading position in fierce market competition.

Impact of environmental regulations on the device market

In Taiwan’s manufacturing industry,Taiwan Environmental Protection RegulationsIt has a profound impact on product production. As the world attaches great importance to environmental protection issues,green manufacturingIt has gradually become an important direction for industrial upgrading and transformation. Naturally, we cannot stay out of the market for PVC micro-injection molding equipment.

In order to comply with theEnvironmental regulationsrequirements, a more environmentally friendly production process must be adopted. This means that both the design and production of devices need to pay more attention to energy efficiency and waste reduction. This kind of change is important for promotingsustainable developmentFor enterprises, it is not only a challenge, but also a new opportunity.

For example, in the design of equipment, using more efficient energy systems can reduce energy consumption in the manufacturing process. In terms of material selection, biodegradable plastics are also increasingly used, which helps reduce the impact on the environment. Taiwan's manufacturers need to constantly update technology to meet increasingly stringentEnvironmental regulations, and realizesustainable developmentThe goal.

In addition, the government's policy subsidies for environmentally friendly products have also brought positive stimulation to the market. Enterprises find a win-win industrial outlet for cost-effectiveness and environmental protection, thereby promotinggreen manufacturingdevelopment in Taiwan.

As a member of the industry, you may need to adjust your production strategies to ensure that your equipment and production processes comply with the latest environmental regulations and are at the forefront of green manufacturing. This is not only to meet legal requirements, but also to reflect corporate social responsibility and inject sustainable development value into your brand.

Market status of injection molding equipment in Taiwan

Taiwan's plastic manufacturing industry has always been the focus of global attention, especially in terms of the rapid development of the injection molding market. Taiwan is known for its high quality and precision craftsmanship, and has become an important base for the plastic injection molding industry.

The expansion of the injection molding market has caused Taiwan's plastic manufacturers to enter a technology and service competition. And you, as a member of Taiwan's plastic manufacturing family, must face the challenge of transformation and upgrading to ensure your competitiveness in the international market.

Facing competitive pressure from around the world, Taiwanese companies are actively seeking innovation, including the research and development of materials, optimization of production processes, and the integration and application of new technologies. These are the key driving forces for Taiwan's plastics manufacturing industry to reach new heights.

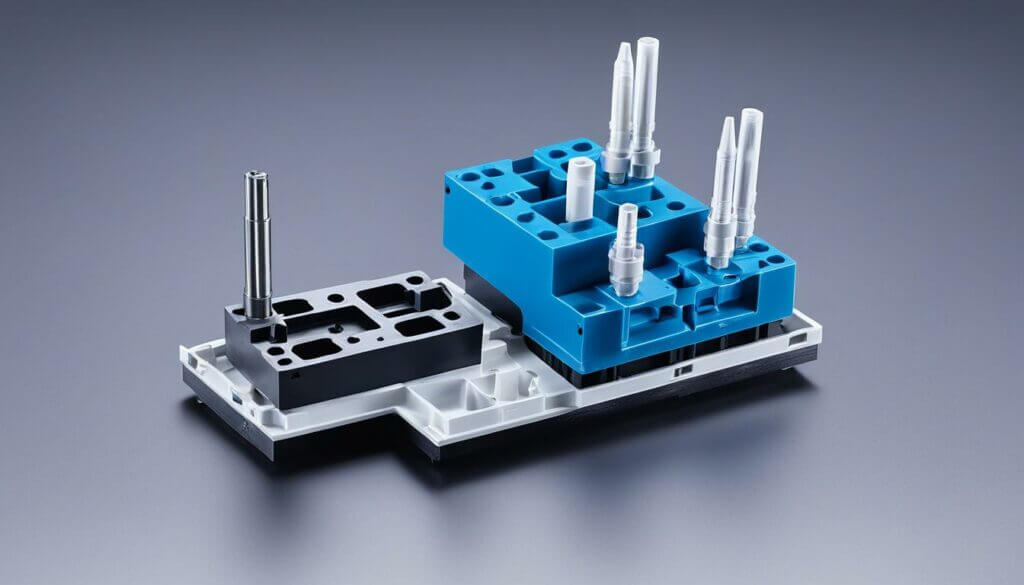

Advantages compared to traditional injection molding equipment

When you evaluate the injection molding device, it is not difficult to find that the PVC micro-injection molding device shows its outstanding advantages in multiple dimensions. fromDevice performance comparisonarriveHigh precision moldrequirements, and then to the overallCost-benefit analysis, this section will make an intuitive comparison between traditional plastic molding equipment and PVC micro-injection technology, so that you can clearly see the advantages of each.

First of all, PVC micro-injection molding equipment provides more precise control capabilities than traditional equipment, which is a key factor when selecting equipment for products that require extremely high-precision molding. Here is a brief performance comparison table to give you a more intuitive understanding of these differences:

| Evaluation indicators | PVC micro injection molding device | Traditional injection molding equipment |

|---|---|---|

| accuracy level | high | middle |

| Production speed | quick | slow |

| Cost of production | more economics | higher |

| Equipment investment | Initial high, long term savings | Low initially, expensive long term |

In addition to direct performance indicators, the PVC micro-injection device can significantly reduce the manufacturing cost of each product due to its high efficiency during use. This point is of particular concern when conducting cost-benefit analysis. The efficient workflow and raw material savings this device enables will ultimately result in significant long-term benefits for your business.

Analysis of major market competitors

When you delve into Taiwan's PVC micro-injection molding equipment market, learn about the industry'sMarket leading brandCrucial. These competitors not only lead the trend in technological innovation, but alsoCompetitive strategy analysisandIndustry competition patternPlay a key role in shaping. The following is a detailed analysis of the market positioning, strategic direction of several major competitors and how they affect the market structure.

| brand name | Market positioning | Competitive Strategy | Market share | Future direction |

|---|---|---|---|---|

| Brand A | Technology innovation leader | Continuous development of high-efficiency injection equipment | 30% | Develop green and environmentally friendly injection equipment |

| Brand B | cost leadership strategy | Reduce production costs and expand market share | 25% | Improve the automation level of injection equipment |

| Brand C | Focus on market segments | Accurately locate customer needs and provide customized solutions | 15% | Expand alliance cooperation and enhance brand influence |

Analyzing each companyMarket leading brand, observe how they change through differentCompetitive Strategyto adjust and stick to yourselfIndustry competition patternposition is particularly important. This not only helps you understand the dynamics of the entire market, but also provides valuable reference information when making investment decisions.

Changes in customer demands and market adjustments

With the continuous evolution of industrial development and consumer market,Customer behavior analysisBecoming the key to manufacturers optimizing their product strategies. Analyzing changes in customer needs can help predict futureMarket demand forecast, thereby adjusting the direction of product development and improvingProduct adaptability. For Taiwan's PVC micro-injection molding equipment manufacturers, this strategy can ensure that their products can meet the new needs of the market.

Let’s understand this process with a practical example: When consumers pay more and more attention to the environmental protection and sustainable production of products, manufacturers must adopt more environmentally friendly materials and upgrade machines to reduce energy consumption. Such market adjustments not only respond to the evolution of customer behavior, but also help expand market share and enhance brand image.

Currently, through data mining and machine learning technology, we are able to conductCustomer behavior analysis. These analyzes not only cover the behavioral patterns of existing customers but also predict opportunities in potential markets. Manufacturers can use this information to adjust and innovate product features to provide products that better meet market demand.

All in all, for Taiwan's PVC micro-injection molding equipment manufacturers, always being able to understand and predict market changes and quickly adjust product strategies is the only way to stay at the forefront of the industry.

Industry supply chain and distribution network analysis

In today's rapidly changing market,Supply chain optimizationBecome an integral part of your business success. Manufacturers of injection molding equipment can effectively reduce costs, increase market response speed and improve customer satisfaction through rigorous distribution channel management. In view of this, a deep understanding of the role of each link in the supply chain, from the procurement of raw materials to the final product reaching the customer, is crucial to keeping the product supply chain smooth.

along withlogistics networkWith development and innovation, Taiwan's injection molding equipment manufacturers have been able to adapt to market demands and changes more quickly and flexibly. Through efficient inventory management and tracking systems, as well as detailed analysis of logistics data, operators can predict market trends and make more accurate production and distribution plans. This approach not only improves the transparency of the supply chain, but also provides customers with higher value.

In summary, the prosperity and competitiveness of the entire industry are based on a stable and flexible supply chain. throughDistribution channel managementWith the effective application of logistics network, Taiwan's plastic injection molding industry can ensure efficient operations and maintain competitive advantages in the fierce market.