Faced with the challenges of industrial production,PVC molding technologyProgress has opened a new door for us. Do you know that in recent yearsMicro injectionexistPrecision plastic moldingA breakthrough? This article will introduce to you in a simple and in-depth wayProcess innovationHow to improve the accuracy and detail processing of PVC molding has had a revolutionary impact on the production efficiency and product quality of the entire plastic manufacturing industry.

Highlights

- Explore the application of PVC micro-injection molding in precision plastic products.

- Learn about the latest process innovations in PVC molding technology.

- Learn how micro-injection can improve the accuracy of product details.

- Learn how to improve production processes and product quality through new processes.

- Preview the future technological development trends in the field of PVC molding.

Introduction to PVC micro-injection molding

When you explore **Micro-volume molding technology**, you will find that PVC micro-volume injection molding occupies a pivotal position in the field of contemporary precision manufacturing. This technology is specifically designed to create small and precise plastic parts, enabling the production of highly detailed products that are far smaller than what traditional injection molding technology can achieve.

Using **Precision Injection Molding**, manufacturers are able to effectively control material flow and filling, and inject PVC melt into purpose-built micro-moulds with incredible precision. This not only improves the accuracy of the overall production process, but also ensures product uniformity and quality consistency.

For a complete **Introduction to Plastic Molding**, the following points are particularly important:

- PVC micro-injection molding makes the production of small plastic parts more flexible and efficient.

- Precision injection molding technology produces industry-leading levels of detail and accuracy.

- Through micro-molding technology, material waste can be reduced, thereby improving production efficiency and cost-effectiveness.

The importance of fine craftsmanship

In this era of pursuing high-quality products and brand characteristics, the technology of high-precision manufacturing is indispensable. When you pay attention to product details and invest resources in **process improvement**, you can significantly improve the overall texture and functionality of the product, which directly affects consumers' purchasing decisions and brand loyalty.

A refined manufacturing process means that every product can meet consistent high standards, both in terms of design accuracy and material quality. The reason is that precisely because of this, precision technology has become an important strategy to enhance the competitiveness of high-quality products. Especially in the fields of precision machinery, high-end electronic equipment, and medical equipment, quality is directly related to the function realization and market performance of the product.

In addition, as technology continues to advance, the market is also constantly evolving. Consumers are no longer just satisfied with the basic functions of products, but also expect highly personalized and exquisitely crafted products. This is an excellent opportunity for manufacturers to use refined processes to give unique value to their products.

Ultimately, when you create a product that meets both functionality and aesthetic boundaries, you'll be able to witness the huge contribution **process improvement** makes to business success. Precision manufacturing is not only a display of technology, but also a symbol of brand strength, so your products will stand out in the fierce market competition.

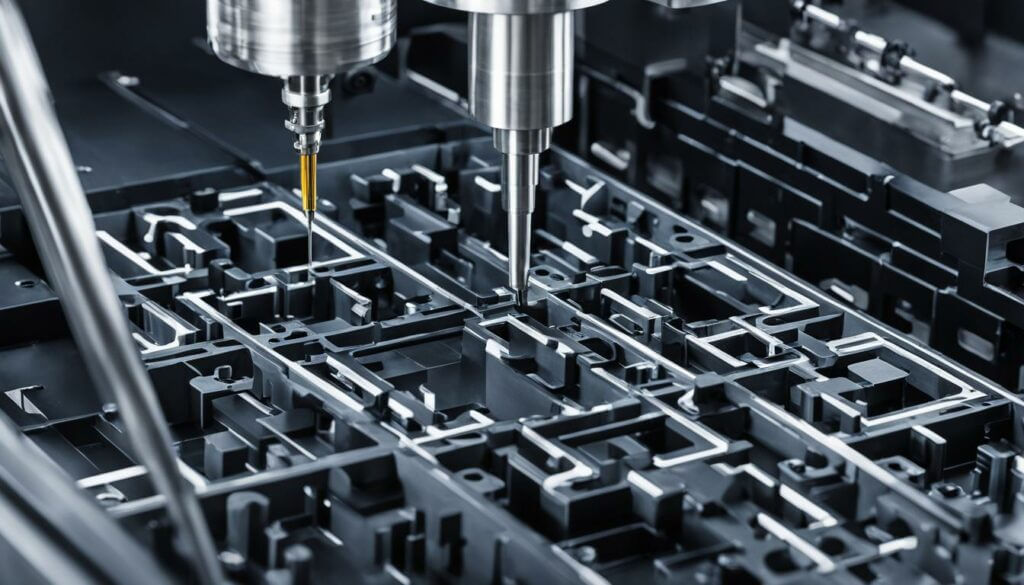

Technological Advances in Injection Molding Machines

In today's manufacturing industry,Injection molding machine innovationhas become the key to improving productivity. along withTechnological development, the new generation of high-precision equipment not only improves the molding quality, but also greatly optimizes production efficiency. These advancements provide you with a solid foundation to stay competitive in the marketplace.

againstHigh precision equipmentTo meet the needs, modern injection molding machines are equipped with sophisticated control systems to ensure the uniformity of injection pressure and temperature consistency. Such innovation not only reduces the waste of raw materials, but also reduces the defect rate during the production process.

For example, the use of multi-axis servo robotic arms improves the speed and accuracy of product removal, and reduces damage to molded products through fine motion control. The application of smart sensor technology allows the machine to monitor production status in real time, conduct data analysis, and achieve preventive maintenance and optimized production.

The rapid development of injection molding machines provesTechnological developmentplays an important role in modern manufacturing. Continuous innovation makes machines more intelligent and green, and the future development prospects are exciting.

Characteristics of refined PVC materials

When you choose the right material for fine PVC micro-injection molding, understanding the **PVC material properties** has an indispensable impact on optimizing the process and improving product quality. Polyvinyl chloride (PVC), as a high-performance plastic, is widely used in the manufacturing of precision plastic parts due to its outstanding physical and chemical properties.

PVC has the following characteristics:

- Excellent chemical stability, resistant to corrosion by most acids, alkaloids and greases.

- High strength and durability allow the product to maintain structural integrity for a long time.

- Good processing performance, easy to shape through injection molding technology.

- The low manufacturing cost, combined with its durability, provides a cost-effective material choice.

Therefore, choosing PVC as the material for micro-injection molding can help you create durable and high-quality precision components. PVC material not only helps improve production efficiency, but also meets a variety of demanding application requirements due to its unique properties.

Detailed control of process flow

When you pursue precise and flawless PVC micro-injection molding products,process controlIndispensable for achieving unparalleled product quality. a perfectProcess managementThe system ensures that every stage from raw materials to finished products is strictly monitored. This can not only significantly improve product consistency, but also effectively reduce resource waste.

Details determine success or failure, inRefinement of detailsOn the road, every step of the process has been carefully planned and rigorously executed. The following is a typical fine PVC micro-injection molding process, showing the industry standards that should take into account quality and efficiency at each stage:

| process stage | control points | quality standards |

|---|---|---|

| Raw material preparation | Ensure that PVC pellets are dry and free of impurities | Pellets humidity <0.02% |

| temperature control | Adjust melting temperature according to material properties | The melting temperature is controlled within the range of ±1℃ |

| Injection pressure | Precisely control injection pressure to avoid shrinkage or scorching | Pressure error range ±5% |

| Cooling time | Moderate cooling based on product thickness and shape | Product free of stress cracks |

| Demolding and post-processing | Smooth demoulding and necessary post-touching | The product surface is defect-free |

Remember, in process management, continuous monitoring and adjustment are key. Your goal should be to maintain the highest standards throughout the entire production process to optimize product quality. When your process can accurately match material properties and machine settings, extraordinary finished products are no longer out of reach.

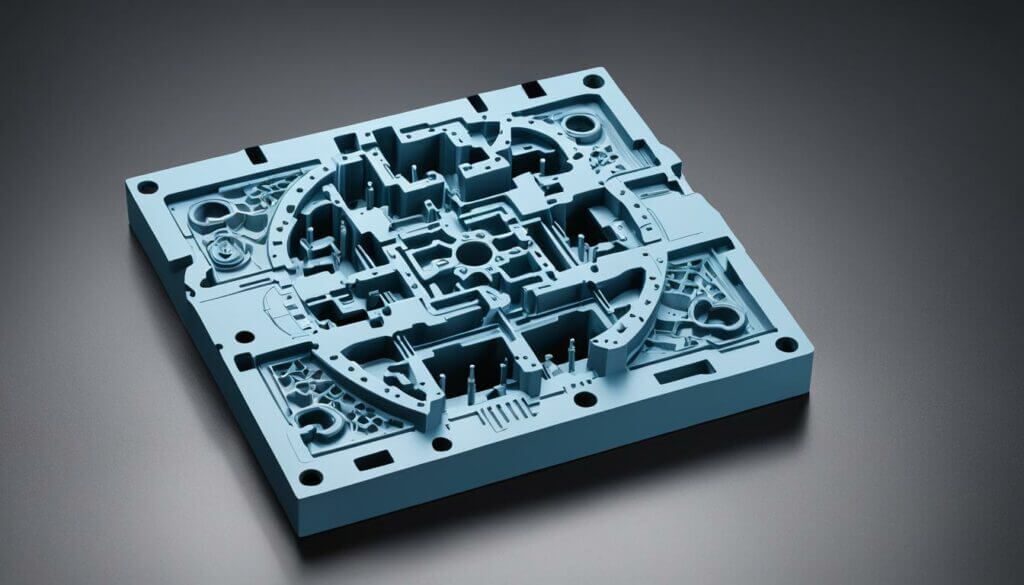

Innovative thinking in mold design

In the current field of precision molding,Mold designinnovation is crucial. A well-designed mold can not only improve production efficiency, but also ensure product quality and meet the market's demand for high-end precision molded products. Innovative craftsmanship todayMold designIt plays a key role in the field, promoting the innovative thinking of designers and realizing the precision molding of various complex products with a high degree of professional knowledge and technology.

| design elements | traditional materials | Innovative materials |

|---|---|---|

| Durability | generally | high |

| Accuracy | accurate | Extremely accurate |

| Cost-effectiveness | higher | Reasonable |

| Design flexibility | limited | widely |

| Production cycle | longer | shorten |

In the face of growing market demand andPrecision moldingWith the development of technology, we must constantly explore newMold designand manufacturing methods. Through innovative processes, we can produce molds that are both precise and durable, thereby promoting technological progress in the entire industry.

Quality monitoring and testing methods

In your pursuit of ultimate precision in the PVC micro-injection molding process,Quality controlandproduct testingplays an irreplaceable role. An effective quality management system can ensure that the quality of products at all stages from design to shipment meets the strictest standards. Brand-newquality assuranceEquipment, such as coordinate measuring machines and optical scanners, provide us with precise measurement data to evaluate and ensure finished product quality.

| Test items | Detection Tool | Testing purpose |

|---|---|---|

| Dimensional accuracy | Three coordinate measuring machine | Ensure product dimensions comply with design specifications |

| surface integrity | Optical scanner | Detect whether there are defects on the product surface |

| color consistency | Colorimeter | Ensure product color consistency and accuracy |

| Material properties | Universal material testing machine | The mechanical properties of the test material meet the requirements |

Strengthening the product inspection process will help to instantly detect possible problems in the manufacturing process and then make adjustments on the production line. This is critical to reducing the scrap rate, improving product consistency and consumer satisfaction. And you, as the executor of quality control, will play an important role in ensuring that PVC micro-injection molding products reach the top level of the industry.

Facing challenging molding of complex shapes

In today's field of precision plastic molding,Complex shape forminghas become an important technical challenge. This not only tests the design innovation ability of engineers, but also is a trial of precise control of precision molding technology. Successfully manufacturing plastic parts with both complex shapes and high precision requires the use of advancedPrecision plastic moldingtechnology and implement strict quality management measures.

In the face of this kind oftechnical challenges, a typical solution step table:

| challenge stage | Technical solutions | Molding advantages |

|---|---|---|

| Mold design | Using 3D printing technology to create prototypes | Quickly respond to design modification requirements |

| material selection | Use high flow plastic materials | Reduce manufacturing costs and improve production efficiency |

| Precision injection | Optimize injection parameter settings | Improve product structural integrity |

| quality control | Implement automated detection system | Ensure product size and functionality are consistent |

Through the implementation of these solutions, it is possible to overcomeComplex shape formingdifficulties to achieve high-quality and efficient production goals. From innovation in mold design to precise injection control and automated quality inspection, every step is key to ensuring product accuracy and efficiency.

Application trends of environmentally friendly materials

With the increasing global awareness of environmental protection,Environmentally friendly materialsIn the plastic manufacturing industry, especially its application in fine PVC micro-injection molding has received great attention. Upholdsustainable productionThe principle of transparency and improving the environmental protection of the production chain has become an integral part of the development of the industry.

Although traditional PVC materials are widely used in various products, their pressure on the environment has gradually emerged. Therefore, the development of PVC alternatives that are recyclable, biodegradable, or even derived from renewable resources is of great significance to the transformation and upgrading of the entire industry. This not only reduces the impact of production on the environment, but also meets modern consumers' expectations for green products.

In addition to material selection,green manufacturingThe process also includes energy-saving and emission-reducing production technologies, waste recycling systems, and environmentally friendly design of the overall process. These measures not only promote the development of the plastic manufacturing industry in a greener and more sustainable direction, but also bring long-term economic benefits to the company itself.

Let us take a look at the new application of environmentally friendly materials in refined PVC micro-injection molding technology through the following pictures:

As you can see, theEnvironmentally friendly materialsIntegrating into traditional manufacturing processes is not only an industrial upgrade, but also a practice of corporate social responsibility. It is our common pursuit to reduce the environmental burden while providing consumers with more secure and environmentally friendly products.

With the continuous development of technology and the gradual transformation of the consumer market, we foresee that environmental protection will become a new normal in the plastic manufacturing industry in the future, and you, the readers, will also be participants and beneficiaries of this change.

Case sharing of PVC micro-injection molding

success caseSharing for understanding PVC micro-injection moldingIndustry applicationbenefits are crucial. Through the demonstration of actual cases, we can witness how this technology is actually operated and applied to solve various production challenges.

In the field of medical equipment, PVC micro-injection molding technology can produce highly precise and hygienic components that play a key role in surgical equipment and diagnostic tools. In the production of precision electronic parts, this technology ensures high stability and precision, and meets the strict requirements for durability and conductivity of extremely small components.

Then, in the application of the automotive industry, it not only improves the production efficiency of complex components, but also brings lighter and more environmentally friendly material options.

| industry | Application examples | effectiveness |

|---|---|---|

| medical equipment | surgical instrument components | Improving precision and hygiene standards |

| Precision electronics | Tiny parts inside smartphones | Ensure component quality and lifespan |

| Car manufacturer | In-car control system buttons | Increase the lightness and environmental protection of materials |

Maintenance and care: extending equipment life

In the field of modern precision manufacturing, goodEquipment maintenancePractice is essential to ensure the best working condition of your equipment and extend its useful life. The following will put forward some practical tips for PVC micro-injection molding machines.Maintenance suggestions.

| Maintenance activities | Recommended frequency | Precautions |

|---|---|---|

| Clean the body | per shift | Wipe with a non-static cloth to avoid dust accumulation |

| Check oil circuit | weekly | Make sure the oil circuit is unobstructed and free of leaks |

| Replace filter | every 3 months | Keep oil clean and extend oil pump life |

| Lubricate moving parts | on demand | Lubricate important moving parts such as guide rails and lead screws |

| Check safety devices | every 6 months | Ensure emergency stops and safety doors function reliably |

Following these simple steps can help you maximize equipment performance and ensure continuous and stable production processes. Ultimately, this not only improves product quality, but also saves companies more maintenance and repair costs.

Future trend: intelligence and automation

when we look aheadThe future of precision manufacturing, found that it is related toIntelligent productionandAutomation technologyThe combination is getting closer and closer. This not only brings major transformation to all walks of life, but also paints an innovative and opportunity-filled blueprint for the future of precision manufacturing.

Smart production is entering a new era. The production line here is not just a collection of automation, but also a data-driven and self-learning intelligent system. By adding artificial intelligence (AI) and machine learning (ML), production systems can now monitor environmental changes in real time and automatically adjust process parameters to maintain optimal operation.

Such progress not only improves the flexibility and efficiency of production, but also reduces dependence on skilled labor to a certain extent, allowing companies to respond to market changes more quickly. Moreover, this integrated smart platform can also play an important role in preventive maintenance and quality control, significantly reducing the rate of errors and defective products.

The future manufacturing scene may no longer be a busy workshop, but an efficient automated factory where robotic arms work accurately and unmanned trucks shuttle back and forth. This enables unmanned management of the entire process from raw materials to finished products, greatly enhancing the competitiveness of your products.

As a result, manufacturers need to rethink how to cope with this trend, especially in digital transformation and talent cultivation. future, embraceIntelligent productionandAutomation technologyenterprises will likely become industry leaders and lead theThe future of precision manufacturingnew trends in development.

in conclusion

After a series of discussions, you should have a deeper understanding of the process reform of refined PVC micro-injection molding. From selecting appropriate materials, mastering advanced molding technology, utilizing innovative mold design, to implementing rigorous quality control, every step is an indispensable link to achieve efficient production.

In practice, the conclusions of fine molding are constantly verified and improved, making PVC micro-injection molding technology not only improve the production efficiency of the manufacturing industry, but also greatly improve the quality of finished products. The evolution and application of this technology have made significant contributions to the development of many industries, especially the medical, electronics and automotive fields.

Looking to the future, with the advancement of intelligence and automation, refined PVC micro-injection molding technology will continue to lead industrial production towards higher quality standards. Is your company ready to face the opportunities and challenges brought about by this wave of process reform?