Explore the PVC micro-injection process. In the 21st century manufacturing industry, you will find that this technology is revolutionizing the production of small precision parts. With the advancement of technology, micro plastic parts are becoming more and more important, and their applications range from medical equipment to consumer electronics. This article will give you a comprehensive introduction to the application of PVC micro-injection and an in-depth discussion of how it has become an indispensable key element for many innovative products.

In the field of micro plastic parts manufacturing, PVC micro-injection has gradually become the focus of the industry due to its high precision and cost-effectiveness. We’ll reveal what makes PVC materials stand out from the crowd of options and how they meet the market’s increasingly stringent specifications for smaller components.

Key takeaways

- Learn how micro-injection of PVC can improve the production process of micro plastic parts.

- Explore the properties of PVC material that make it an ideal micro-injection option.

- Understand the wide range of applications of PVC micro-injection in various industries.

- Understand the growing market demand for micro plastic parts and its impact.

- Master the key technical points of designing high-quality micro plastic parts.

What is PVC micro injection?

PVC micro-injection is a high-precision plastic injection molding technology specially used to manufacture small and fine plastic parts. This technology can accurately control the amount of plastic material injected into the mold, and is a key manufacturing process in industries such as **medical equipment**, **electronic products** and **precision machinery parts**.

In order to have a deeper understanding of the process of PVC micro-injection and its advantages, the following table will display relevant key information:

| Features | benefit | Application examples |

|---|---|---|

| Precision measurement control | High precision and consistency | medical microcatheter |

| Less material waste | Cost effective and environmentally friendly | smart watch components |

| Can handle complex shapes | Design flexibility | Micro acoustic components |

By using PVC micro-injection technology, manufacturers can achieve higher production efficiency and product quality, while reducing material loss during the manufacturing process. This technology has an increasingly wide range of applications and is an indispensable manufacturing solution for industries pursuing innovation and efficiency.

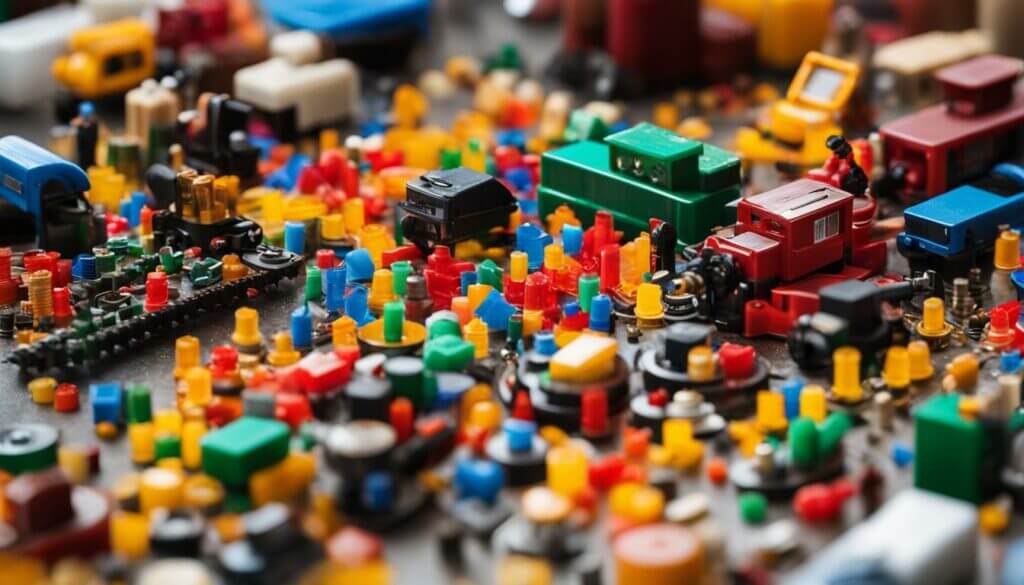

Market demand for micro plastic parts

With the continuous advancement of science and technology, micro plastic parts are increasingly used in many industries and have become an important element in promoting innovation. Market demand for these high-precision, high-performance components continues to grow, especially in the consumer electronics, medical equipment, and automotive industries. These parts not only need to meet precise size requirements, but also have good chemical stability and physical properties to adapt to various complex and harsh usage environments.

It is particularly worth mentioning that with the rise of portable and wearable devices, such products are particularly dependent on micro plastic components. Not only do these components need to be compact, they also need to be lightweight and durable to keep the overall device portable and long-lasting. Therefore, the quality and production efficiency requirements for these components have reached unprecedented levels.

The development history of micro-injection technology

When you explore the history of microinjection technology, you'll find that it is a field that continues to evolve. In the early days, engineers faced many challenges, including how to precisely control the flow and cooling of plastic to create tiny, precise plastic parts. Over time, the technology has undergone a transformation from manual operations to semi-automation to today's fully automated production lines.

In Taiwan, micro-injection technology is growing rapidly in response to the booming development of consumer electronics, medical equipment and precision industries. This technology not only improves production efficiency and reduces manufacturing costs, but also improves product consistency and quality. Over the past few decades, microinjection technology has evolved from a mere manufacturing process to a high-tech process integrating advanced control and monitoring systems.

It is important to note that micro-injection capabilities are still evolving today. With the development of digitalization and smart manufacturing, this technology will gradually be combined with the concept of Industry 4.0 to further promote the manufacturing industry towards a smart and automated future.

Reasons for choosing PVC as the material for micro-injection

In today's field of micro plastic parts manufacturing, PVC material stands out due to its excellent properties and has become the first choice of many engineers and designers. PVC, or polyvinyl chloride, is not only easy to process, but also offers high strength, chemical resistance and excellent durability. The following will discuss one by one why PVC can stand out among many materials and become an ideal choice for micro-injection.

High flexibility:By adding different plasticizers, the hardness and flexibility of PVC can be adjusted according to the needs of the product, making it suitable for different application fields.

Excellent chemical stability:PVC's ability to resist corrosion from various chemicals allows it to be used in environments that require long-term exposure to chemical solvents.

Good insulating properties:As an insulator, PVC is often used in micro-components in the electronic and electrical fields to ensure the safe operation of devices.

Environmentally friendly and renewable:With the popularization of the concept of green environmental protection, the recyclability of PVC has also become an important consideration in material selection.

In response to your needs for precision micro plastic parts, the characteristics of PVC during the micro-injection process fully meet the diverse requirements from durability to flexible design, which is why PVC has broad application prospects in this field.

Application fields: Diverse uses of PVC micro-injection

PVC micro-injection technology plays an indispensable role in many industries due to its flexibility and high efficiency. From medical equipment to consumer electronics, plastic parts made of PVC are widely used because of their lightweight, durability and cost-effectiveness.

| Application areas | Product examples | Key advantages |

|---|---|---|

| medical equipment | Disposable syringes, pipeline connectors | Hygienic, high precision, low cost |

| Consumer Electronics | Smartphone buttons and connectors | Lightweight, friction-resistant and beautiful |

| Automobile industry | Instrument panel buttons, electronic component kits | High temperature resistance, chemical resistance and durability |

| Household goods | Faucets, valves, small hardware | Safe, waterproof, long life |

These application examples highlight the high applicability of PVC micro-injection in the design and production of high-precision plastic parts, bringing unlimited possibilities to your business.

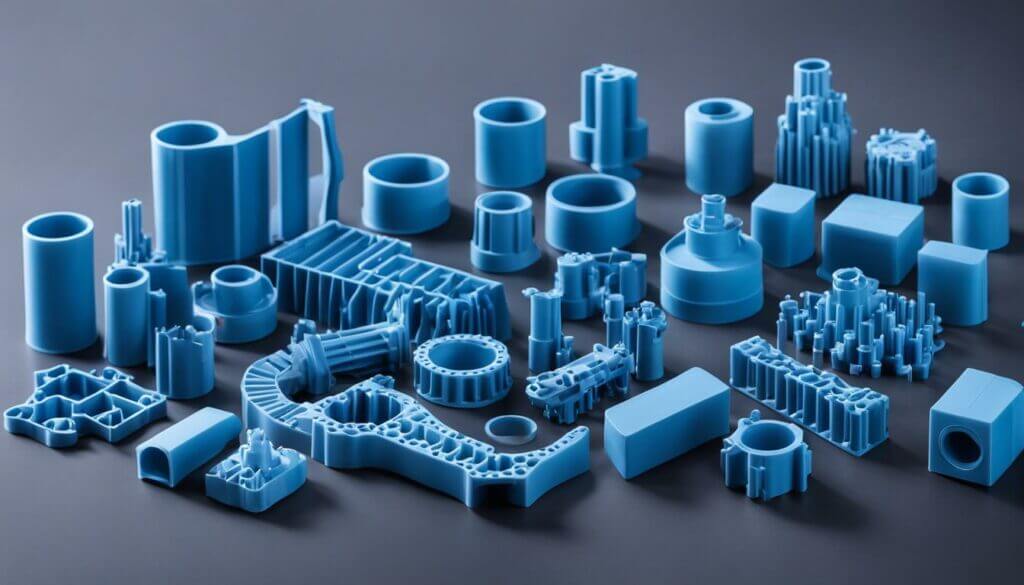

Key points in designing micro plastic parts

In today's manufacturing industry,Micro plastic partsThe design is a precise and complex process. Through precise design, product functions can not only be improved, but manufacturing costs can also be reduced. Here are some key considerations when designing micro plastic parts.

first,Dimensional accuracyIt is the primary consideration in the design of micro plastic parts. Any slight error may cause problems during assembly or application of the part. Based on this, designers need to use accurate engineering software to ensure correct dimensions.

Secondly,material selectionAlso critical, choosing the right materials can improve the performance and longevity of the component. For example, PVC is often used in micro-injection processes because of its chemical resistance and high strength.

| design elements | consider principles | scope of influence |

|---|---|---|

| Dimensions and tolerances | Accurate calculation, taking into account shrinkage during injection | Assembly, coordination and function realization |

| Material properties | Heat, impact, and chemical resistance | Component life, reliability |

| Wall thickness design | Avoid excessive thickness leading to uneven cooling | Surface quality, product stability |

| Runner system | Ensure material flows evenly | Finished product quality, production efficiency |

| Exhaust system | Effectively exhaust gases to prevent defects | Surface integrity and perfect structure |

finally,Mold designandprocess controlIt is also an element that cannot be ignored. Excellent mold design is the basis for achieving high-quality micro components, while strict process control ensures the stability of the process and the consistency of the components.

In response to the needs of the target market, designing micro plastic parts that meet the required functions and quality standards of the application can stand out in the fiercely competitive market.

Equipment selection: efficient micro-injection machine

When you enter the world of micro plastic parts manufacturing, choose the rightMicro injection machineis the key to success. High-efficiency equipment can improve product quality, enhance productivity, and reduce operating costs. In this section, we’ll explore how to choose a micro-volume injection machine that meets your needs.

| Features | benefit |

|---|---|

| Precise control | Ensure consistency and repeatability of product manufacturing processes |

| Energy-saving design | Reduce energy consumption and achieve environmentally friendly production |

| Automation functions | Improve production efficiency and reduce operator burden |

| Quick mold change system | Shorten production mold change time and quickly respond to market changes |

In choosingMicro injection machineWhen doing so, you should consider the machine’s control system, power efficiency, degree of automation, and ease of maintenance. With the ideal equipment, you will be able to stably produce high-quality micro plastic parts to meet the growing market demand for precision micro components.

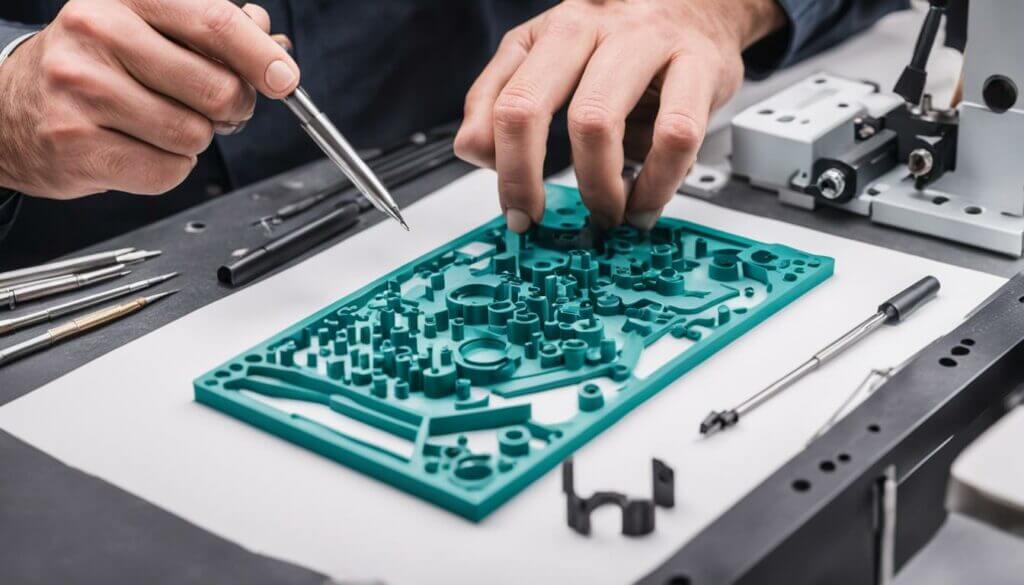

The importance of mold design in micro-injection

In the micro-injection process, mold design is not only related to product quality, but also directly affects the efficiency and cost of the entire production. A sophisticated mold can ensure that the micro plastic parts produced have excellent precision and complexity, and can also help reduce production cycle and material waste.

Driven by advanced micro-injection technology, mold design innovation is catering to the booming needs of industries such as medical, consumer electronics, automotive and aerospace, which often require extremely high-specification small plastic components. Therefore, mold designers need to keep up with the latest industry standards and have a deep understanding of material properties and injection processes.

Choosing appropriate mold materials and designing fine details are the keys to ensuring product quality. Common micro-injection mold materials on the market include heat-treated tool steel or carbide, which can provide good wear resistance and long service life while ensuring high precision.

In addition, the optimization of the internal structure of the mold is also crucial. Including the design of the exhaust system, the layout of the cooling channels, and even the design of the demoulding mechanism, careful calculations and testing are required to ensure the consistency and reliability of the final product.

For your micro-injection project, choosing an experienced mold design and manufacturing partner will be a key step to improve product performance and market competitiveness.

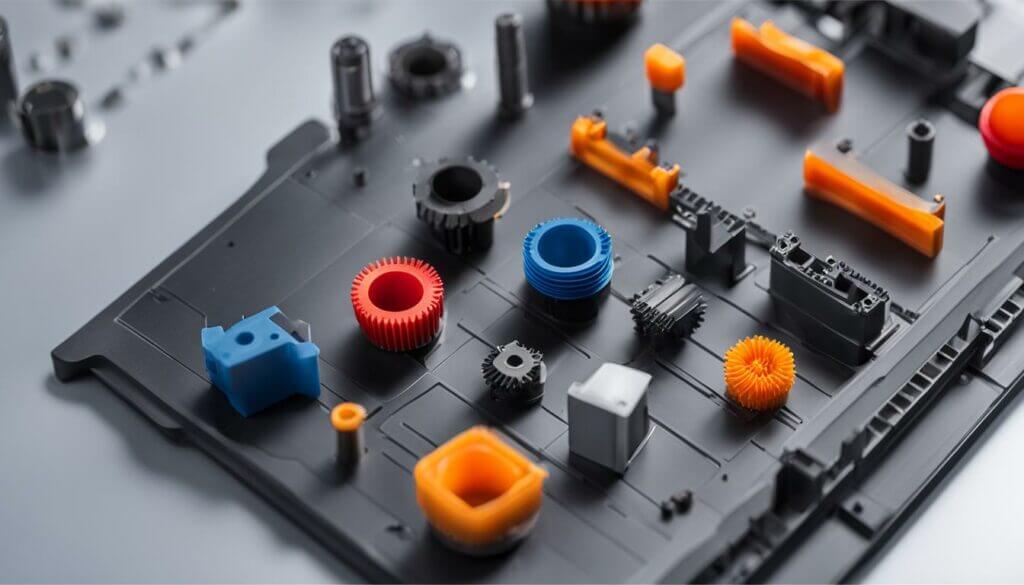

Production process: steps from design to finished product

When you face a new generation of micro-injection projects, understanding the entire production process will help you optimize time and costs. This section will introduce in detail the important production stages of PVC micro-injection to help you smoothly transform your design concepts into high-quality finished products.

| stage | describe | Related notes |

|---|---|---|

| Concept Design | Based on market demand, a preliminary design of micro plastic components is drafted. | Ensure designs are manufacturable and meet performance and size specifications. |

| material selection | Choose appropriate PVC materials to adapt to the application environment and performance requirements of the product. | Consider the physical and chemical properties of the material as well as its cost. |

| detailed design | Refine product design and complete the conversion from concept to actual product. | Conduct mold design and anticipate potential production challenges. |

| prototyping | Use 3D printing or CNC machining to create preliminary prototypes to verify design assumptions. | Perform functional and structural testing of prototypes. |

| Mold making | Make molds based on the final design for subsequent mass production. | Mold accuracy directly affects product quality and needs to be strictly controlled. |

| Micro injection production | Use professional micro-injection machines for mass production. | Maintain consistent PVC temperature and pressure during production. |

| Post-processing | Including cleaning, painting, assembly and other processes. | Post-processing improves product appearance and ensures functionality. |

| Quality inspection | Through high-precision equipment, we ensure that the quality of each component meets standards. | Unqualified products must be reprocessed or scrapped. |

| Packaging and shipping | Packaging is carried out according to customer requirements to ensure the safety of products during transportation. | Flexible logistics arrangements meet the market’s needs for rapid response. |

Mastering these steps will speed up your process from idea to realization, creating an advantage for your micro plastic part manufacturing, both in terms of production efficiency and market competitiveness. There are many details involved in PVC micro-injection, and each detail has an impact on the quality and performance of the final product that cannot be ignored.

Quality control: ensuring the accuracy of micro plastic parts

In the production process of micro plastic parts,quality controlIt plays a decisive role in ensuring the accuracy and reliability of products. We understand the details in depth. From material inspection, production process monitoring to finished product testing, every step is an important link to ensure that your products meet the highest standards in the industry.

First of all, when raw materials enter the market, a professional team will conduct strict quality inspections.Ensure compliance with micro-injection molding requirements. Material texture, purity, and fluidity will be comprehensively tested to control accuracy in subsequent production processes.

During the production process, high-precision equipment and advanced monitoring systems continuously track production links, including key parameters such as injection speed, pressure, and temperature. This real-time data is critical to detecting problems promptly and maintaining product quality.

The completed micro plastic parts will undergo a series of performance tests, such as dimensional inspection, mechanical property testing and life testing, to provide a comprehensive quality report. Through this complete quality assurance process,Customer trustand market competitiveness will be improved at the same time.

Material innovation: research direction of environmentally friendly PVC

Facing today's environmental protection challenges, research and development of environmentally friendly PVC has become a popular area of material innovation. Environmentally friendly PVC not only meets the requirements of sustainable development, but also provides the dual advantages of effectively reducing production costs and improving product performance. As an industrial R&D personnel, you will be able to deeply understand the dual environmental and economic benefits brought about by material innovation.

Compared with traditional PVC, environmentally friendly PVC releases significantly fewer harmful substances during the production process, and is more efficient in recycling and processing. To discuss the research direction of environmentally friendly PVC, the author has compiled the following key points that you need to pay attention to:

| Research focus | Practical application | environmental impact |

|---|---|---|

| Non-phthalate plasticizer | Improve the flexibility of plastic parts | Reduce burden on ecosystems |

| Bio-based materials | Substitute traditional petrochemical raw materials | Reduce carbon footprint |

| Biodegradable PVC | Improve waste disposal | Promote resource recycling |

Although environmentally friendly PVC is still in the research stage, its potential in the field of micro-injection is already well known. As technology breakthroughs and market demand increase, you can expect significant progress in this field in the coming years.

Let us join hands and look forward to the fact that new developments in environmentally friendly PVC will bring a new round of industrial revolution to the manufacturing industry of micro plastic parts, and at the same time provide solid support for protecting the earth on which we live.

Cost Analysis: Economic Benefits of PVC Micro Injection

For you who are engaged in precision industry, it is important to understand the cost structure of PVC micro-injection. Investing in the production of high-precision micro plastic parts will not only improve product quality, but also reduce production costs in the long run. In this section, we will provide an in-depth analysis of the return on investment (ROI) and total cost of ownership (TCO) of PVC micro-injection.

To understand the costs in more detail, the following table will provide a direct comparison between PVC micro-injection and traditional processes, pointing out the cost differences in raw materials, energy consumption, labor and maintenance. With this data, you can better evaluate the economic benefits of microinjection technology.

| cost type | PVC micro injection | Traditional manufacturing process |

|---|---|---|

| Raw material costs | lower | higher |

| Equipment investment | High initial investment | Low initial investment |

| Energy consumption | lower | higher |

| labor cost | reduce | higher |

| Productivity | higher | lower |

| Maintenance cost | lower | higher |

| waste disposal | More economical | high cost |

As can be seen from the table above, although the initial cost of equipment investment for PVC micro-injection may be higher, due to its lower raw material costs and energy consumption, as well as higher production efficiency, it can significantly save costs in the long term. In addition, since less waste is produced in the process, the cost of waste disposal is also reduced. The decline in labor costs is due to the increase in automation, which requires less labor in the production process. Taking these factors into account, you can clearly see the advantages of PVC micro-injection in overall cost management.

Case study: Successful PVC micro-injection application case

When we discuss the successful cases of PVC micro-injection, you will find that this technology has been widely used in many innovative fields. These applications not only demonstrate the precision and efficiency of micro-injection, but also prove the reliability of PVC materials under high-performance requirements.

Leading medical device manufacturers have utilized PVC micro-injection technology to produce tiny, precision plastic parts used in a variety of surgical and therapeutic devices. For example, micro-vascular clips or attachment devices with complex shapes are all made through precise micro-injection processes. These components require extremely high precision and consistency, and micro-injection of PVC enables mass production while maintaining consistent quality.

In addition, the consumer electronics industry is also an important user of PVC micro-injection technology. In mobile phones, tablets and other portable devices, a large number of tiny PVC plastic parts are needed to fix or connect internal parts. Like micro-components for microphones and speakers or connectors, PVC not only provides excellent electrical insulation properties, but also excellent chemical and physical resistance, all of which are necessary for modern consumer electronics.

In these cases, we can see the profound impact of PVC micro-injection technology in various industries. Whether it is medical, consumer electronics or other industries that require precision plastic parts, PVC has demonstrated its key role with its excellent physical properties and cost-effectiveness.

Challenges and Solutions: Problems faced by micro-injection technology

As technology advances,Micro injectionPlay an increasingly important role in the industry. But it also faces some challenges, such as how to balance efficiency and cost, how to ensure product precision and consistency, and how to adapt to rapidly changing market demands. Understanding these challenges and their solutions is critical to staying competitive.

| challenge | solution |

|---|---|

| Cost Control | Optimize production processes and use automated equipment to reduce labor costs |

| Precision and consistency maintenance | Use advanced testing equipment and implement strict quality control systems |

| material selection | Continuously research and develop new materials to improve product performance |

| environmental impact | Use environmentally friendly PVC and recyclable materials to reduce waste generation |

| Rapid changes in market demand | Improve the flexibility of design and mold manufacturing and shorten the product development cycle |

againstMicro injection technologyFacing these challenges, we must continue to innovate and adjust strategies to ensure that technology and market demand evolve simultaneously. In addition, strengthening collaboration with supply chain partners is also the key to achieving efficient production.

Future Outlook: Development Trend of PVC Micro Injection Technology

In Taiwan, PVC micro-injection technology is heading towards an innovative future. As technology advances, we foresee more efficient production processes, more sophisticated injection molding capabilities, and substantial progress in environmental sustainability. For you, these trends mean that lower-cost, higher-quality products will gradually become the new standard in the market.

We can expect that with the advancement of Industry 4.0, smart manufacturing will become the mainstream of micro-injection technology. Through the integration of the Internet of Things (IoT), production data will be tracked and optimized in real time, error rates will be further reduced, and unprecedented production efficiency will be achieved. The feedback of these data will play a key role in the quality management and innovation of PVC materials.

From an environmental perspective, **researchers** are working hard to develop a new generation of PVC materials that will significantly improve its recyclability and biodegradability. With the promotion of eco-friendly plastics, PVC micro-injection will be able to comply with increasingly stringent environmental regulations while satisfying the public's pursuit of a green lifestyle.

With the rise of emerging markets, medical devices, precision engineering and consumer electronics will all be important growth points for micro-injection technology. By then, you will witness more innovative micro plastic parts being used in various high-end equipment, thereby promoting breakthroughs and development in related industries.

in conclusion

Through the discussion in this article, you have a comprehensive understanding of the advantages, application scope and technological development of PVC micro-injection in the manufacturing of micro plastic parts. From the evolution of micro-injection technology to the many benefits of choosing PVC as a material, every point points to how this technology keeps pace with market needs and provides innovative solutions for various industries.

Facing the future, the development trend of PVC micro-injection technology shows that this is not only a major progress in the field of plastic manufacturing, but also the intersection of industrial design innovation and environmental sustainable development. Along with material innovation and optimization of production processes, the advancement of this technology will undoubtedly continue to affect the prospects of industries such as medical, electronics, and automobiles.

In your journey of exploring PVC micro-injection technology, I hope this article can serve as a solid guide to help you find opportunities in the industry, break through limitations, and push your innovative thinking to new heights.