In the face of today's rapid technological innovations, have you paid attention to the role of elastic silicone in the new printing field? Since all-polymer transistor printing was first demonstrated in 1994, it has brought unprecedented opportunities for flexible integrated electronic devices on plastic substrates. The innovative use of elastic silicone not only improves the damage resistance of these devices, but also greatly expands the diversity of their forms and components, further promoting the potential for low-cost and large-area production.

However, there are many challenges in creating flexible devices that are both low-cost and have advanced electronic performance. For example, traditional printing technology is incompatible with plastic materials in high-temperature processing, and materials such as amorphous silicon also limit performance improvements. Fortunately, breakthroughs in elastomeric silicone printing technology provide new solutions to these challenges. Next, let’s explore these new possibilities and their significance for the future of printing technology.

Key takeaways

- Elastic silicone brings revolutionary mechanical robustness and diverse form factors to flexible integrated electronic devices.

- The new printing technology overcomes the traditional challenge of high-temperature incompatibility with plastic materials.

- Elastic silicone enables low-cost, high-volume production of flexible electronic devices.

- Innovative elastic printing technology provides the possibility of higher resolution patterning.

- The selection and optimization of elastic materials directly affects the market competitiveness of electronic products.

Development and application fields of silicone elastic materials

As you explore the world of flexible integrated electronics, you will noticeSilicone developmentThis is a major leap forward for this field. Silicone is highly elastic and durable, which makesFlexible integrated electronic devicesEnabled in many innovative designs, everything from electronic paper to advanced medical devices.

Plastic substrateThe ruggedness gives electronic components incredible mechanical stability while also providing the necessary flexibility to adapt to a variety of body shapes and usage environments. It is this characteristic that opens up the possibility of seamlessly integrating electronic products into daily life. assimilate intoFlexible silicone applicationsFinally, you can imagine silicone materials making electronic devices more malleable and further expanding their range of uses.

Here are some examples of various elastomeric silicone application areas that highlight the important role silicone plays in the advancement of flexible electronic devices:

| Application areas | Advantages of silicone materials | Related product examples |

|---|---|---|

| wearable technology | Skin-friendly and highly elastic | Smart bracelets, health monitoring equipment |

| medical device | Biocompatibility, chemical resistance | Implantable sensor, elastic catheter |

| Flexible display | Excellent transparency, heat resistance | Bendable smartphone screens |

| smart home | ductility, weather resistance | Wall-mounted control panel, sensor device |

As you can see, withSilicone developmentWith the continuous advancement, its application prospects in flexible integrated electronic devices have also expanded, creating diversified and humanized technological solutions. undoubtedly,Flexible silicone applicationswill continue to serve as a driving force for technological innovation.

Market demand for flexible electronic devices and the role of elastic silicone

With the rapid development of science and technology,Flexible electronic devicesDemand in the market continues to heat up. In order to adapt to the increasingly changing application environment,Elastic siliconeBecause of its excellent physical properties, it is becoming an indispensable material in the electronic component industry.

Expanding applications of flexible electronic devices driveMarket demandsurge. From smart wearables to advanced medical devices, elastic silicone plays a central role in innovative electronic products due to its adaptability and durability. Such materials not only make products more durable and flexible, but also make product design and manufacturing processes more cost-effective.

Faced with the rapid growth of flexible electronic devices, how should you seize the opportunity?Elastic siliconeWhat about the opportunities it brings? The following are the main applications of elastic silicone in different fields, which may give you some direction.

| Application areas | The role of elastic silicone | market trend |

|---|---|---|

| wearable device | Improve product comfort and wearing elasticity | Wearable technology user base is growing rapidly |

| Flexible display | Enhance the damage resistance of display panels | Rising demand for entertainment and information displays |

| Medical equipment | Comply with physiological curves and achieve accurate monitoring | Increased demand for personalized medicine |

Innovation in new elastic silicone printing technology

In today's high-tech, fast-paced environment,Flexible silicone printingShows endless possibilities. thisInnovative TechnologyBreaking through previous material limitations and opening up a new world with a high degree of freedom and flexibilityHigh resolution patterningnew chapter. You'll see how formulation innovation and processing techniques can significantly improve costs while reducing costs.Printing efficiencyPhenomenon.

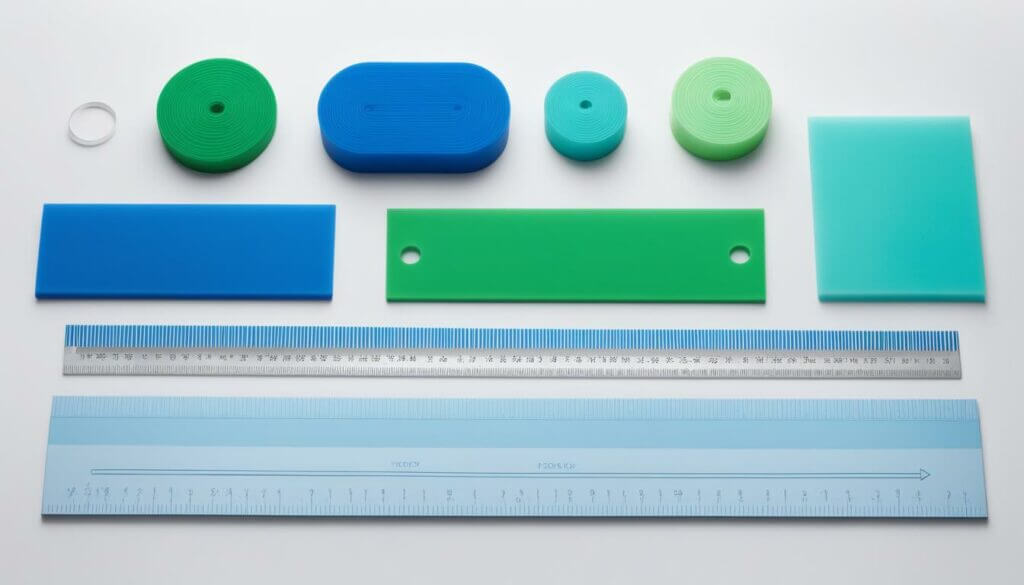

As the demand for plastic substrates increases, the application of elastic silicone becomes more and more widespread. The combination of solution-processed silicone rubber material and high-performance plastic substrate not only makes the patterns in the printing process more detailed, but also enables a new era of rapid printing. Effectively combining flexibility and durability, this technology is committed to bringing more creative electronic solutions to the market.

| characteristic | traditional printing technology | New elastic silicone printing technology |

|---|---|---|

| Material flexibility | limited | extremely high |

| Printing resolution | generally | high resolution |

| Manufacturing efficiency | lower | extremely high |

| Cost-effectiveness | higher | more economical |

| Patterning complexity | limited | unlimited |

With the advancement of this new printing technology, companies will be able to meet consumers' needs for high-quality, multi-functional electronic products, thus opening up a wider market space. Flexible silicone printing has established its indispensable position in the high-tech industry with its innovation and practicality.

Solving manufacturing challenges for flexible electronic devices

In the field of flexible electronic device manufacturing, the incompatibility between high-temperature processing and plastic materials has always been a big challenge. The good news is,Silicone rubber propertiesThe prominence and continuous advancement of materials provide us with effective solutions to challenges. Specifically,Elastic siliconeThe use of it shows its unique value in this regard.

Compared with traditional inorganic semiconductors, elastic silicone has better compatibility and is suitable for low-temperature processing. With the help of innovative research and development of these materials, high-efficiency thin film transistors and new micro- and nanoscale materials can be widely used on elastic substrates.

This is exactly what the market needs, and flexible electronic device manufacturers are increasingly pursuing flexibility and productivity. You can imagine that by applying these new materials and technologies, future electronic devices will no longer be subject to rigid and fragile physical limitations.

| Challenge type | Flexible silicone solutions | expected benefit |

|---|---|---|

| Not compatible with high temperature processing | Use low-temperature curing elastic silicone | Expanding substrate material selections |

| Material rigidity limits | Introducing highly elastic silicone rubber as substrate | Produce more flexible electronic devices |

| Low production efficiency | Flexible silicone compatible with rapid manufacturing processes | Improve production efficiency and reduce costs |

| Product application is limited | Silicone rubber performance supports multiple device designs | Unlock more innovative applications of electronic devices |

Through solutions and technological advancements like this,Flexible electronic device manufacturingThe future is getting progressively brighter. Elastic silicone not only brings innovative opportunities to the electronics industry, but also brings more convenience and imagination to our daily lives.

The combination of flexible display technology and silicone

along withFlexible display technologyThe rapid development ofSilicone bondinghas become a key element in pushing the boundaries of display even further. In the field of alternating current electroluminescence (ACEL) technology, this combination not only provides superior deformability properties, but also ensures system stability and durability.

The flexible application of silicone rubber expands its use inShow textilesandSensor applicationsof various possibilities. Whether as part of wearable devices or integrated into more complex multi-functional flexible displays, silicone rubber enables these devices to become more closely integrated with daily life and professional work areas.

The role of silicone rubber in promoting luminescent fiber and luminescent film technology cannot be underestimated. The new products developed are not only beautiful, but also bring functionality to a whole new level. Research in this area continues to make breakthroughs, helping product innovation move from the laboratory to the mass market.

Can you imagine a future where clothing lights up with unique patterns, or where your sports equipment displays sports data in real time? These are all passing throughFlexible display technologyandSilicone bondingWith our efforts, it is slowly becoming a reality.

Strategies to Improve Performance of Plastic Substrate Integrated Electronic Devices

As the demand for plastic substrate integrated electronic devices continues to grow, strategic development has become the key to improving performance. Today's technological development allows us to see that it is feasible to use innovative silicone materials, especially elastic silicone rubber, to improve the overall performance of plastic substrate integrated electronic devices. Through new thin-film transistor designs and advanced nanotechnology, silicone rubber not only shows high compatibility with plastics during the device manufacturing process, but can also significantly improve product durability and performance.

The following is our detailed analysis of strategy development, which will help you understand the impact of different strategies on how to improve the performance of plastic substrate integrated electronic devices:

| Strategy | describe | Performance impact |

|---|---|---|

| Nanomaterial Technology | Improving silicone rubber structures using nanowires and nanostrips | Increase conductivity and sensitivity of electronic devices |

| Thin film transistor optimization | Developing more efficient thin film transistor structures | Increase switching rates and reduce energy consumption |

| Highly integrated design | Implementing dense, highly integrated circuit layouts on plastic substrates | Improve overall device bulk and reduce size |

At this stage, the use of high-performance silicone rubber materials is particularly important to improve the performance of plastic substrate integrated electronic devices. It not only makes the device stronger, but also improves the versatility of the product. As you consider strategic product development, these upgrade guides can provide you with informed choices.

New application of coating technology in silicone printing

In the development in recent years,Coating technologyexistSilicon printing applicationshas demonstrated unprecedented innovation and progress. The optimization of these technologies not only makes the printing process more precise, but also greatly improves the quality of the product.surface functionalityandProductivity. Below we discuss the revolutionary application of coating technology in modern silicone printing and the substantial benefits it brings.

| Coating technology characteristics | Before coating | After coating |

|---|---|---|

| Printing performance | uneven coating | Even and fine coating |

| Boiling resistance | Weak resistance to water intrusion | Significantly improved boiling resistance |

| Smooth properties | High surface friction | Optimized surface for better touch |

| Cost of production | High cost materials and processes | Improve efficiency and reduce costs |

As can be seen from the above table,Coating technologyThe application and optimization can not only improve the coating uniformity in silicon printing, but also be of great help in improving the boiling resistance and smoothness of the product. At the same time, this technological improvement can also enhanceProductivity, Reduce the economic burden of enterprises in the production process.

Optimizing material selection for silicone elastic printing

When you pursue excellent quality of printed products,Silicone material selectionCan not be ignored. Your choice directly affects the product's high transparency and high tear resistance properties, both of which are crucial performance indicators in the flexible printing market. To achieve these properties, you may consider using high-quality fumed silicones. This material not only offers transparency comparable to liquid silicone, but also has excellent tear resistance, making it an ideal choice for solid silicone.

existFlexible printing optimizationIn the process, you can also precisely adjust material properties according to application requirements. Whether you are pursuing a longer service life or need to meet a specific hardness range, the diversity of silicone materials allows it to be flexibly adapted to various complex situations. The silicone materials introduced this time can not only improve product performance, but also bring you significant advantages in production efficiency and cost-effectiveness.

The Importance of Flexible Silicone Printing in Modern Electronics

when you facemodern electronic productsWhen the changing requirements ofFlexible silicone printingProvides a revolutionary solution. This printing technology relies on its excellentVersatilityand excellenceSilicone rubber performance, helping the product resist daily wear and adapt to various usage environments.

The versatility of elastic silicone printing enables it to be widely used in various electronic devices including smartphone screens, wearable devices, medical instruments, and various sensors. This technology not only enhances the durability of the product, but is also closely integrated with advanced display technology to provide an unparalleled user experience.

| Application areas | Silicone rubber performance | market trend reaction |

|---|---|---|

| Smart device | Provides elasticity and drop resistance | High demand growth |

| Wearable device | Thin, flexible, comfortable and skin-friendly | Rapid popularity |

| Medical equipment | High biocompatibility and non-toxic | Innovative medical solutions |

| sensor | High accuracy and good response to environmental changes | emerging market development |

all in all,Flexible silicone printingThe development ofmodern electronic productsbrought revolutionary progress. As technology continues to develop and innovate, we can expect more efficient and multi-application electronic devices to bring more convenience to our lives in the future.

Explore the impact of silicone material properties on the printing field

When you deeply understand the profound impact of silicon material properties on the printing field, you will find that driven by technological progress, silicon is not only widely studied as a new material, but its physical and chemical properties are also gradually changing our Knowledge of traditional printing techniques.

Silicone's excellent elasticity, excellent temperature resistance and significant plasticity give it unparalleled potential for innovative applications in the printing and manufacturing industry, especially in the production of micro electronic components and large-area displays. This is especially true in many areas where technology is advancing rapidly, such as flexible displays, wearable devices, and biomedical sensors.

As more research is invested in silicon performance improvement and manufacturing process optimization, silicon materials will undoubtedly bring higher production efficiency and a wider range of applications to the printing field. You can expect that printing technology in the future will be increasingly integrated into every aspect of daily life.

Innovative processing and patterning technology of silicone elastic materials

In recent years,Silicone innovative processingandpattern technologyrapid progress, allowinghigh resolution printingandMaterial handlingThere have been revolutionary changes in the field. The highly developed technology not only makes the printing process more precise, but also reduces the error rate, ensuring product quality.

| Technical features | benefit | Application examples |

|---|---|---|

| Silicone innovative processing | Improved material utilization and reduced waste | High temperature resistant electronic component packaging |

| High-resolution pattern technology | Improved accuracy and better presentation of details | Tiny sensors for wearable devices |

| Flexible material handling | Adapt to various complex shapes and increase designability | Flexible display screen |

Through the application of these technologies,youIt can realize more complex and detailed device design, whether it is medical equipment, smart wearable devices or applications in the aerospace industry, it can achieve a qualitative leap.

In the future, with the continued development of new materials and process technologies,Silicone elastic materialInnovative applications in various industries will become even more important, thus pushing the entire high-tech manufacturing industry to new milestones.

Price advantage and economic effect analysis

In the increasingly competitive market environment of modern printing technology,price advantageandEconomic Effectsare two core factors that play an important role in evaluating new materials such asFlexible silicone costand its impact on corporate investment returns. You'll find that elastomeric silicones offer opportunities to improve your production processes and maximize return on investment through precise cost control and high throughput efficiencies.

Economic principles tell us that low-cost investments can usually bring high profits. As an innovative material, elastic silicone not only has low cost in the manufacturing process, but also has breakthroughs in product performance, which makes it also have significant economic benefits.return on investment.

| Material type | cost | Durability | Productivity | ROI |

|---|---|---|---|---|

| Traditional silicone rubber | medium | Low | medium | medium |

| Elastic silicone | Low | high | high | high |

As shown in the table above, compared with traditional silicone rubber,Elastic siliconeDemonstrates its value in many ways. In particular, the improvement in durability and production efficiency is directly reflected in the increase in return on investment, which brings not only cost savings to manufacturers, but more importantly, the strengthening of market competitiveness.

Combined with an appropriate product development strategy and the application of these materials, your business can secure a favorable position in the market and achieveprice advantageand excellentEconomic Effects.

Environmental protection regulations and the future direction of silicone materials

Facing today'sEnvironmental protection regulationsof increasing attention,The future of silicone materialsThe development trend undoubtedly points togreen manufacturingandsustainable development. With its excellent physical properties and environmentally friendly characteristics, silicone is regarded as an ideal choice for plastic replacement, especially in the field of high-standard environmental protection. In order to meet these specifications, silicone not only needs to maintain its existing non-toxic and recyclable characteristics, but also needs to continuously optimize its production process and resource efficiency through innovation.

As awareness of environmental responsibilities deepens, companies and consumers are more concerned about complying withEnvironmental protection regulationsThe demand for products is growing day by day. Combining silicone materials with green technology has become the focus of the industry. From the procurement of raw materials to the production of final products, every step follows green manufacturing principles to reduce energy consumption and waste generation.

In the future, silicone materials will further develop their biodegradable properties while maintaining strength and flexibility, thereby providing more environmentally friendly solutions without sacrificing product performance. This can not only meet the market's demand for environmentally friendly products, but also help companies better respond to relevant environmental protection regulations and demonstrate the company's green image.

| Current Silicone Material Properties | Environmental protection optimization goals | Estimated path to achieve |

|---|---|---|

| Non-toxic | Development of biodegradable materials | Materials Science Innovation |

| recyclable | Improve recycling efficiency | Advances in recycling and processing technology |

| Durability | Achieve long life without sacrificing environmental protection | Material strengthening research |

| manufacturing cost | Low carbon production process | Energy management and optimization |

As a consumer, when purchasing a product you should consider whether it complies withEnvironmental protection regulations, and prioritize those committed tosustainable developments brand. Enterprises need to continue to innovate and study how to useThe future of silicone materialsThe application and implementation of greenergreen manufacturingexpectations.

Breakthroughs in processing technology and high-efficiency applications of elastic silicone

In today's technology industry,Processing technology breakthroughIt has become one of the important driving forces for innovation. You may have noticed that the wide range of applications of elastic silicone is an outstanding example of this innovative processing technology. With the continuous advancement of these technologies, we can now manufacture higher-quality electronic products at lower costs, which is very important for the electronics field.High performance applicationsHave far-reaching consequences.

through continuous improvementProcess improvement, new applications of elastic silicone are gradually being realized. The material's plasticity and stability make it ideal for making electronic components that are both flexible and durable. You may have witnessed it in various consumer electronics productsFlexible silicone innovationbrought about huge changes.

You must be looking forward to how this type of material will further change our daily lives in the future. Well, continue to pay attention to the further applications of elastic silicone in various fields, because this will determine many aspects of our future lifestyle, especially in wearable devices, medical equipment, and the diverse use of flexible electronics.